YantraAI

YantraAI

YantraAI

YantraAI

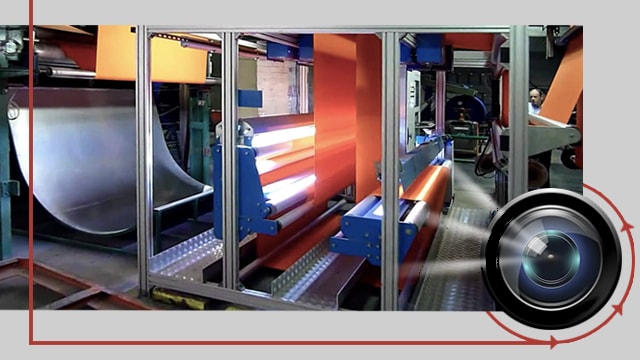

Yantra AI's cutting-edge solutions optimize your textile production, quality control, and supply chain management with unprecedented precision and efficiency.

Our comprehensive AI solutions address every aspect of textile manufacturing, from raw material inspection to finished product quality control.

Computer vision systems detect defects with 99.7% accuracy in real-time, reducing human error and increasing throughput.

Learn MoreReduce downtime by 40% with AI-driven equipment monitoring and predictive failure analysis.

Learn MoreOptimize inventory and logistics with demand forecasting and real-time tracking solutions.

Learn MoreDiscover the powerful features that make our textile AI solutions stand out from the competition.

Instant identification of weaving defects, color variations, and material flaws with our advanced computer vision technology that learns and improves over time.

AI algorithms analyze production data to maximize throughput while minimizing waste and energy consumption across your entire operation.

Comprehensive tracking and reduction of water, energy, and chemical usage across your production facilities with actionable insights.

Our clients consistently achieve significant improvements across key operational metrics.

Our AI solutions are transforming every stage of textile production.

Automated visual inspection that outperforms human capabilities in speed and accuracy.

End-to-end quality control from cutting to final assembly.

Precision control for consistent, sustainable coloration.

We leverage cutting-edge technologies to deliver unparalleled textile manufacturing solutions.

Find answers to common questions about our textile AI solutions.

Our system achieves 99.7% accuracy in defect detection, significantly outperforming human inspectors who typically achieve 70-80% accuracy. The AI continuously learns and improves over time, adapting to new defect patterns and material variations.

Most implementations are completed within 4-8 weeks, depending on the complexity of your operation and the number of inspection points. Our team works closely with yours to ensure minimal disruption to your production schedule during installation and training.

Yes, our solutions are designed to integrate seamlessly with most existing textile manufacturing equipment. We support standard industrial communication protocols and can develop custom interfaces when needed. Our engineers will assess your specific setup during the consultation phase.

Our clients typically see ROI within 6-12 months through a combination of reduced waste, lower labor costs, decreased customer returns, and increased production efficiency. The exact timeframe depends on your specific operation and which solutions you implement.

We offer flexible pricing models including subscription-based SaaS options and traditional perpetual licenses. Pricing is based on the scale of your operation and the specific solutions you require. Contact us for a customized quote tailored to your needs.